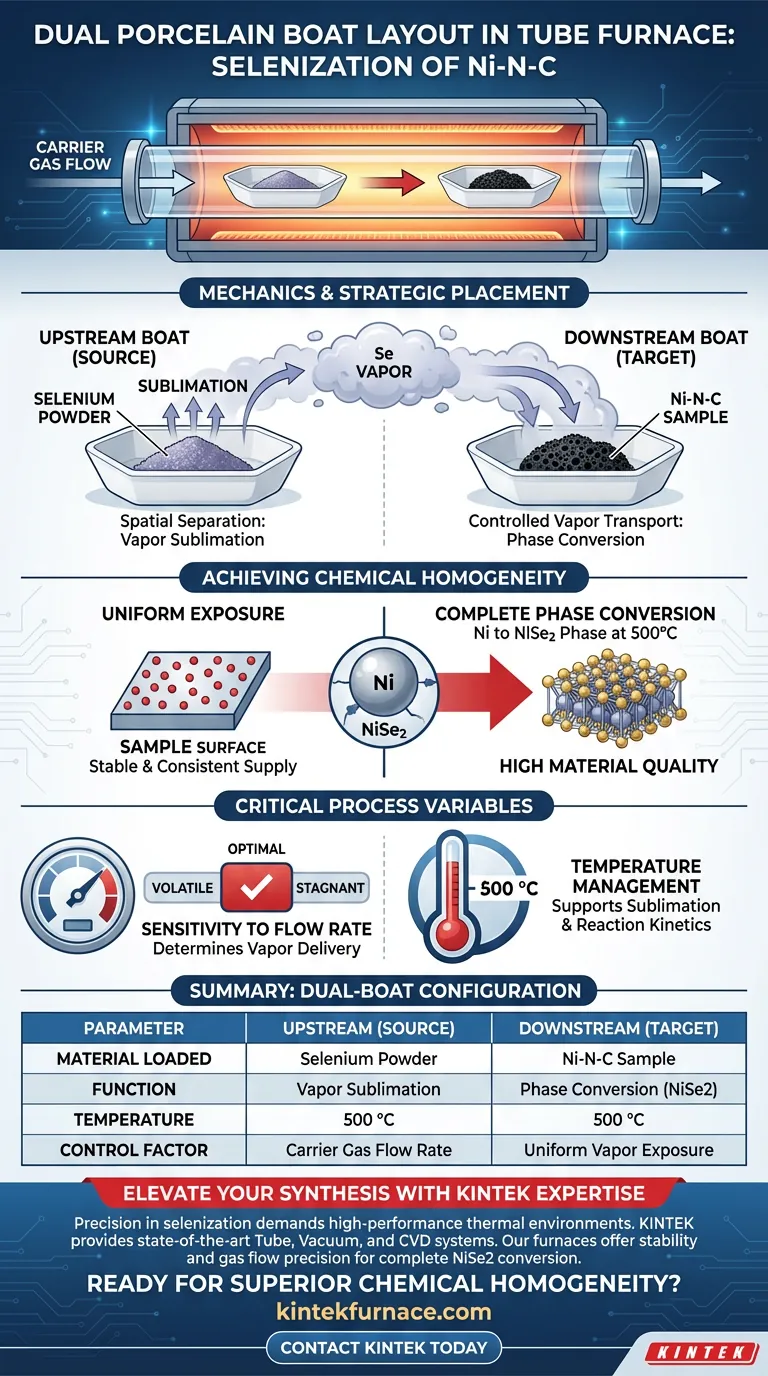

The dual porcelain boat layout serves as a spatial control mechanism for vapor deposition within the tube furnace. By placing selenium powder upstream and the Ni-N-C sample downstream, this configuration utilizes the carrier gas to transport sublimated selenium vapor uniformly across the target surface, preventing uneven reaction kinetics.

The physical separation of the source and the target is the key to stability. This arrangement ensures a consistent, continuous supply of selenium vapor, which is critical for achieving the complete conversion of nickel nanoparticles into the NiSe2 phase.

The Mechanics of the Dual-Boat Configuration

Strategic Component Placement

The fundamental principle of this layout is spatial separation. You place the selenium powder in the first porcelain boat, located upstream relative to the gas flow.

The Ni-N-C sample is placed in the second boat, located downstream. This ensures the sample interacts only with the vaporized selenium, rather than solid contact.

Controlled Vapor Transport

Once the furnace reaches temperature, the selenium sublimates into a vapor. The carrier gas acts as the transport vehicle, moving this vapor from the upstream boat toward the downstream sample.

Precise control of the gas flow rate is essential here. It dictates how quickly and densely the selenium vapor is delivered to the Ni-N-C surface.

Achieving Chemical Homogeneity

Ensuring Uniform Exposure

A single-boat setup or improper spacing can lead to uneven deposition. The dual-boat layout, however, facilitates a stable and consistent supply of reactant.

By relying on gas transport, the selenium is distributed evenly across the entire surface area of the downstream sample.

Complete Phase Conversion

The ultimate goal of this consistency is chemical transformation. At a processing temperature of 500 °C, the uniform supply of selenium drives the reaction to completion.

This specific environment allows the nickel nanoparticles within the Ni-N-C matrix to fully convert into the NiSe2 phase, ensuring high material quality.

Critical Process Variables

Sensitivity to Flow Rate

While the layout provides the structure, the carrier gas flow rate is the variable that determines success.

If the flow is too volatile, the selenium vapor may pass the sample too quickly to react. If the flow is too stagnant, the vapor transport becomes inconsistent.

Temperature Management

The process relies on maintaining the specific processing temperature of 500 °C.

You must ensure that the thermal profile of the furnace supports both the sublimation of the upstream selenium and the reaction kinetics at the downstream sample.

Making the Right Choice for Your Goal

To maximize the effectiveness of the dual porcelain boat layout, consider your specific objectives:

- If your primary focus is Phase Purity: Ensure the temperature is strictly maintained at 500 °C to guarantee the complete conversion of Ni to NiSe2.

- If your primary focus is Surface Uniformity: Prioritize the precision of your carrier gas flow rate to ensure the selenium vapor is distributed evenly across the downstream boat.

The dual-boat configuration effectively decouples the reactant source from the reaction site, giving you the control necessary to engineer precise nanomaterials.

Summary Table:

| Parameter | Upstream Boat (Source) | Downstream Boat (Target) |

|---|---|---|

| Material Loaded | Selenium Powder | Ni-N-C Sample |

| Function | Vapor Sublimation | Phase Conversion (NiSe2) |

| Temperature | 500 °C (Sublimation) | 500 °C (Reaction) |

| Control Factor | Carrier Gas Flow Rate | Uniform Vapor Exposure |

Elevate Your Material Synthesis with KINTEK Expertise

Precision in selenization requires more than just a layout; it demands a high-performance thermal environment. KINTEK provides state-of-the-art Tube, Vacuum, and CVD systems designed for the rigorous demands of nanomaterial engineering.

Our furnaces are backed by expert R&D and manufacturing, offering the stability and gas flow precision necessary for complete NiSe2 phase conversion. Whether you need a standard setup or a customizable system for your unique research needs, we deliver the reliability your lab deserves.

Ready to achieve superior chemical homogeneity? Contact KINTEK today to discuss your high-temp furnace requirements!

시각적 가이드

참고문헌

- Qiaoting Cheng, Hua Wang. Modification of NiSe2 Nanoparticles by ZIF-8-Derived NC for Boosting H2O2 Production from Electrochemical Oxygen Reduction in Acidic Media. DOI: 10.3390/catal14060364

이 문서는 다음의 기술 정보도 기반으로 합니다 Kintek Furnace 지식 베이스 .

관련 제품

- 석영 또는 알루미나 튜브가 있는 1700℃ 고온 실험실 튜브 용광로

- 실험실용 1400℃ 머플 오븐로

- 1200℃ 제어 불활성 질소 대기 용광로

- 고압 실험실 진공관로 석영 관로

- 1200℃ 분할 튜브 용광로 실험실 석영 튜브가있는 석영 튜브 용광로

사람들이 자주 묻는 질문

- 수평관상용로 구매 시 고려해야 할 사항은 무엇인가요? 열 공정을 위한 주요 요소

- 수평 전기로의 주요 장점은 무엇입니까? 우수한 공정 제어 및 접근성 달성

- 진공관로를 구매할 때 고려해야 할 사항은? 정밀도와 성능을 위한 핵심 요소

- 튜브로에서 튜브 챔버에 사용되는 재료는 무엇입니까? 귀하의 실험실 고온 요구 사항에 맞는 올바른 튜브 선택

- FTO 박막 어닐링에 대기 제어 튜브 퍼니스를 사용하면 어떤 이점이 있습니까?

- 70mm 관상로의 주요 특징은 무엇인가요? 실험실을 위한 고온 정밀도를 확보하세요

- Pt@A&R-TiO2 소성 시 정밀한 온도 제어가 가능한 튜브로가 필요한 이유는 무엇인가요? 촉매 상 최적화

- LiMn2O4 코팅에서 실험실 튜브 어닐링로의 역할은 무엇인가요? 전문가의 후처리 통찰력